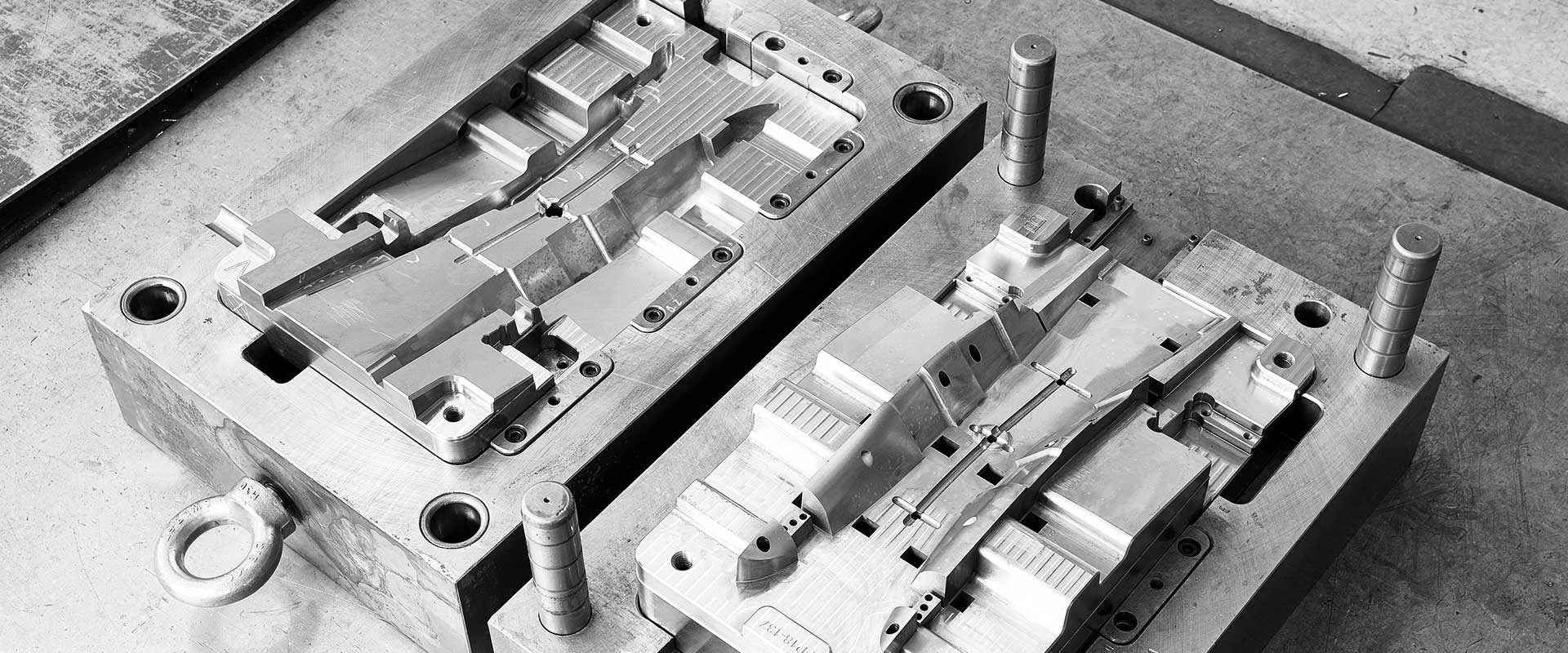

Aluminum Mold Making: A Comprehensive Guide by Prototool Manufacturing Limited

Mold making is a critical aspect of the manufacturing process, and it has a significant impact on the quality of the final product. Aluminum molds have become increasingly popular due to their superior quality, durability, and cost-effectiveness. Prototool Manufacturing Limited is a company that specializes in aluminum mold making, and in this article, we will discuss the advantages of Aluminum Mold Making, the different types of molds, and the steps involved in the mold-making process.

Advantages of Aluminum Mold Making

Aluminum molds have several advantages over other materials such as steel, wood and Plastic Prototype. These advantages include:

-

Durability: Aluminum molds can withstand high temperatures and pressure without warping or cracking, making them ideal for high-volume production runs.

-

Cost-effectiveness: Aluminum is a cheaper material than steel, and it is easier to machine, reducing production costs.

-

Faster turnaround time: Aluminum molds can be machined faster than steel molds, reducing the time required for production runs.

-

Lightweight: Aluminum is a lightweight material, making it easier to handle and transport, reducing shipping costs.

Types of Aluminum Molds

There are several types of aluminum molds, including:

-

Prototype molds: These are used to produce small quantities of parts for testing and validation before full-scale production.

-

Production molds: These are used for high-volume production runs and can produce thousands of parts.

-

Composite molds: These are made by combining aluminum with other materials such as plastic or fiberglass to produce more complex molds.

-

Injection molds: These are used for injection molding and are designed to produce parts with complex geometries.

Steps Involved in Aluminum Mold Making

The mold-making process involves several steps, including:

-

Design: The first step is to design the mold using CAD software. This includes specifying the dimensions, materials, and other specifications required for the mold.

-

Machining: Once the design is complete, the mold is machined using CNC machines to create the required shape and size.

-

Polishing: The mold is then polished to achieve a smooth surface finish, which is critical for producing high-quality parts.

-

Testing: The mold is tested to ensure that it can produce parts that meet the required specifications.

-

Production: Once the mold has been tested and validated, it is used for production runs to produce the required number of parts.

Conclusion

Aluminum mold making is a critical aspect of the manufacturing process, and it offers several advantages over other materials. Prototool Manufacturing Limited specializes in aluminum mold making and can help you create molds that meet your specific requirements. With our expertise in mold making, we can help you produce high-quality parts quickly and cost-effectively. Contact us today to learn more about our aluminum mold-making services.

Comments

Post a Comment