Plastic injection moulding advantages

Thing recognizing verification expects a basic part in conferring what is going on and brand in the business place. Plastic nameplates can pass on messages, brand, portrayals, depiction, schematics, reprimands, bearings and various types of thing information.

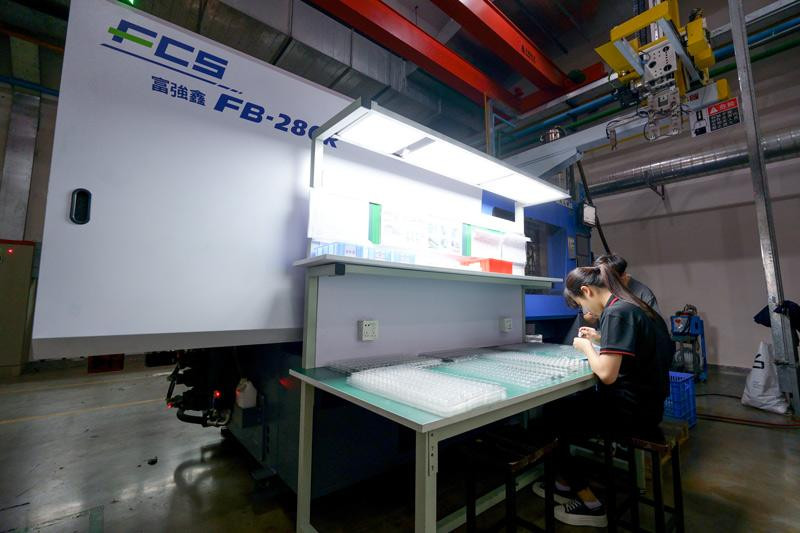

Plastic mixture framed nameplates help to perceive your things and help them with charming everybody. Before we go further, we ought to explore the plastic mixture forming cycle.

The Plastic Mixture Trim Cycle

The plastic mixture molding cycle is certainly not a tangled one. Framing patterns of this sort including metals return various years, and crucial principles have not changed, just the techniques and materials.

Clearly, you have seen what the finished thing looks are. You've seen them a greater number of times than you could be aware of. You've seen them as vehicle images, contraption and present day nameplates, custom plastic nameplates, donning thing nameplates, spot to checkout, plaques and signs. They fill your overall environmental elements, yet do you have at any rate some thought how are they made?

The cycle begins with a plastic pellet made of a composite of regular and inorganic polymers, notwithstanding added substances to help the conditioning framework. This little pellet is tossed into a holder with extraordinary various pellets. This starts the outing from pellet to thing. The accompanying stage is setting up the plastic.

The pellets are conveyed onto the strings of a goliath turning screw. As the pellets travel along, they are warmed to melting temperatures, some place almost 400 degrees Fahrenheit. Clearly, the more noteworthy the plastic is the higher temperature it takes to relax it. The pellets are moved along the screw because the cycle moreover requires disintegration and power. The screw gives both as the pellets overlay along its surface and crash into each other.

Now that all of the three essentials are met, grinding, power and force, the pellets begin to gather and the ensuing phase of filling begins. The screw continues to coordinate the liquid plastic along its strings to a valve. Under high strain the valve controls the plastic into an uncommonly created structure - made of force safe metals - until each opening is filled. At the point when this is achieved the structure goes into the holding stage. The filling and holding stages are critical stages in the plastic implantation molding cycle. Their execution will choose the idea of the finished thing. The metals we use for the shape safeguard that the last piece made conveys comparative attributes as the first.

The Accompanying stage

The pressure on the structure is stayed aware of while the fluid plastic cools to areas of strength for a. This stage could require several minutes as the structure holds the force from the disintegrated plastic, and hence is cooled by coolant that walls it in. While the part is cooling, the screw returns to its one of a kind position, assembling extra pellets from the holder. The thing is then darted away from the structure and moves to its discretionary cycles like enhancement, sub social occasion, or shipment. Yet again the shape closes, and the cycle begins.

Advantages of the Plastic Implantation Frivolity

There are a couple of huge advantages of utilizing imbuement framed plastic:

The plastic implantation framing licenses amazing and confounding shapes to be created. Shapes that would be exorbitantly irksome or costly to make with different cycles.

The plastic implantation molding considers a high volume of plastic nameplates and custom plastic signs to be manufactured at the same time with a comparative structure and quality.

The metal molds have a long life. Exactly when you return for a future solicitation, the shape will be ready and your next solicitation will be vague from your first. In addition, their basic cost is low too.

The plastic nameplates can be further developed in various ways like surfaces in the structure, metallic foil, ink, UV confirmation, and that is just a glimpse of something larger.

For More Info : -

Plastic Injection Molding Machine

Comments

Post a Comment